Nickel Alloy Wire

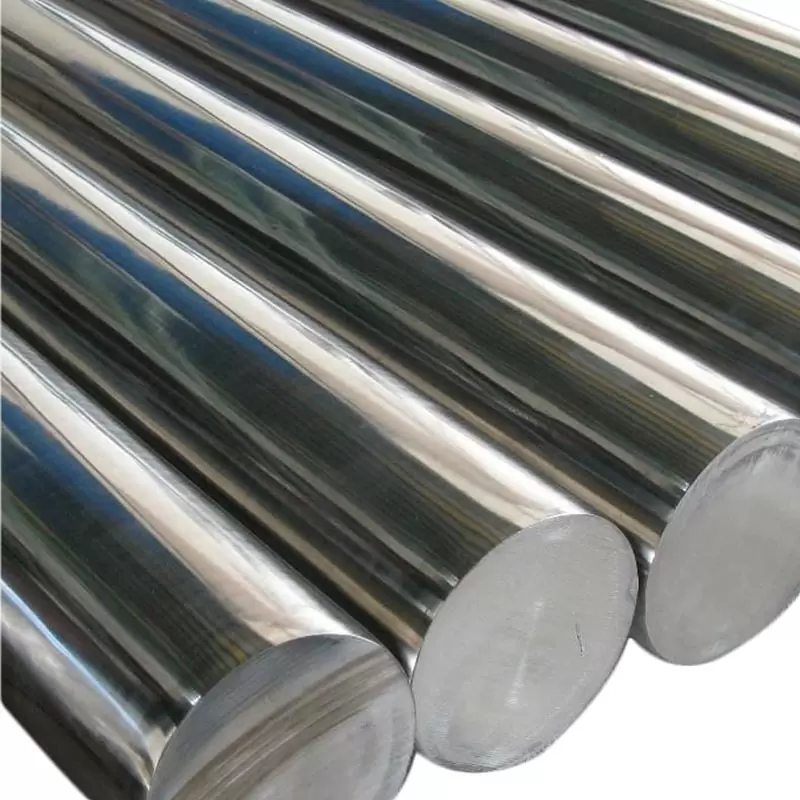

Nickel alloy wire is a highly versatile material with a wide range of applications across various industries. It is made from nickel-based alloys that are specifically developed to exhibit superior properties such as high strength, excellent corrosion resistance, and good electrical conductivity.

Request A Quote?

Product Details

Nickel alloy wire is a highly versatile material with a wide range of applications across various industries. It is made from nickel-based alloys that are specifically developed to exhibit superior properties such as high strength, excellent corrosion resistance, and good electrical conductivity.

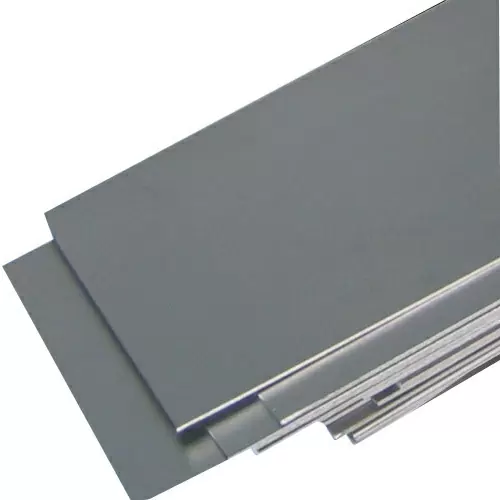

Alloy Steel Description

| Product Name | Nickel Wire |

| Type | Wire |

| Diameter | 0.1-5.0mm |

| Length | c |

| Standard | ASTM,JIS, AISI, GB, DIN, EN |

| Surface | BA,2B,NO.1,8K |

| Certification | ISO, SGS |

| Price Term | CIF CFR FOB EX-WORK |

| Payment Terms | T/T L/C and Western Union etc |

Chemical Properties of Frequently-used Stainless Steel Material Grade

| DIN/EN | UNS NO | The international communication | Introduction of weld material | |

| 1 | 2.4060 | N02000 | Nickl200 | E(R)-Ni-1 |

| 2 | 2.4601 | N02201 | Nickl201 | E(R)-Ni-1 |

| 3 | 2.4050 | N02270 | Nickl270 | / |

These characteristics make nickel alloy wire an ideal choice for demanding applications in aerospace, electronics, chemical processing, automotive, and many other sectors.

One of the primary advantages of nickel alloy wire is its exceptional corrosion resistance. Nickel, as the primary component, provides excellent resistance to corrosion, including both general and localized forms. This property makes nickel alloy wire well-suited for use in aggressive environments, such as in chemical processing plants handling corrosive substances, offshore oil and gas operations exposed to saltwater, and marine equipment subject to harsh conditions.

Nickel alloy wire is also widely used in the aerospace industry due to its high strength-to-weight ratio and resistance to elevated temperatures. It is utilized in critical applications including aircraft engine components, electrical wiring, and sensor systems. The combination of its mechanical strength and temperature resistance allows the wire to withstand the extreme conditions encountered in aerospace applications, ensuring reliable performance and safety.

In the electronics industry, nickel alloy wire is utilized for various purposes including heating elements, resistors, and conductive wires. The wire’s high electrical conductivity, along with its corrosion resistance, thermal stability, and low temperature coefficient of resistance, make it an excellent choice for applications that require precise and reliable electrical performance.

Nickel alloy wire is also employed in the automotive industry, particularly in engine components, exhaust systems, and electrical connections. Its ability to withstand high temperatures and corrosive gases makes it suitable for demanding automotive environments. Additionally, its high strength ensures durability and longevity, contributing to the overall performance of automotive systems.

Chemical processing plants extensively use nickel alloy wire in equipment such as pumps, valves, and heat exchangers. The wire’s resistance to corrosion from acids, alkalis, and other corrosive chemicals ensures the reliability and efficiency of these systems. Its mechanical strength and temperature resistance enable it to withstand the high pressures and temperatures involved in chemical processing operations.

Furthermore, nickel alloy wire finds applications in the medical field, particularly in dental and orthopedic implants. Its biocompatibility, corrosion resistance, and high strength make it an ideal material for medical devices that must function reliably within the human body. In addition, the wire’s non-magnetic properties are advantageous in medical imaging applications, such as MRI machines.

In summary, nickel alloy wire is a versatile material with excellent properties that make it highly suitable for numerous industries. Its corrosion resistance, high strength, electrical conductivity, and temperature stability enable its use in applications ranging from aerospace and electronics to automotive, chemical processing, and medical fields. Nickel alloy wire plays a vital role in ensuring the performance, reliability, and safety of a wide range of systems and products.