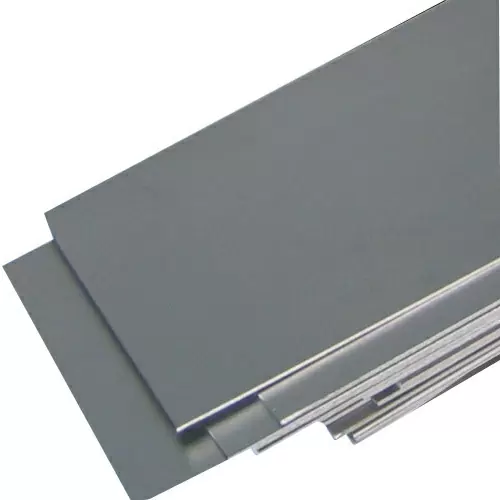

Nickel Alloy Plate

Nickel alloy plates are versatile materials that possess excellent corrosion resistance and high-temperature strength. They find use in various industries for a wide range of applications.

Request A Quote?

Product Details

Nickel alloy plates are versatile materials that possess excellent corrosion resistance and high-temperature strength. They find use in various industries for a wide range of applications.

Alloy Steel Description

| Product Name | Nickel Plate |

| Type | Plate |

| Thickness | 0.3-150mm |

| Length | 3000mm,5800mm,6000mm,9000mm,12000mm,etc. |

| Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Standard | ASTM,JIS, AISI, GB, DIN, EN |

| Surface | BA,2B,NO.1,NO.4,4K,HL,8K |

| Certification | ISO, SGS |

| Technique | Cold Rolled, Hot Rolled |

| Edge | Mill Edge Slit Edge |

| Quality | SGS Inspection |

| Price Term | CIF CFR FOB EX-WORK |

| Payment Terms | T/T L/C and Western Union etc |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

Chemical Properties of Frequently-used

| MATERIALS | GB | ASME/ASTM | DIN | JIS | SPECIFIC GRAVITY g/cm3 | CONTENT |

| NICKEL | N4 | N02201 | 2.4068 | NLC | 8.9 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.10C |

| NICKEL | N6 | N02200 | 2.4066 | NNC | 8.9 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.10C |

| NICKEL | N02270 | 2.4050 | 8.9 | 99.9Ni-0.02Fe-0.001Mn-0.002Si-0.005Cu-0.01C |

Here are some common scopes of use for nickel alloy plates:

1. Chemical processing industry: Nickel alloy plates are extensively used in chemical processing plants where they come into contact with corrosive chemicals, acids, and alkaline solutions. They are employed in reactors, columns, heat exchangers, and storage tanks.

2. Petrochemical industry: Nickel alloy plates are well-suited for the petrochemical industry, particularly in processes involving the transportation, refining, and storage of petroleum and natural gas. They are used in equipment like heat exchangers, condensers, piping systems, and storage tanks.

3. Power generation: Nickel alloy plates are utilized in power plants, both conventional and nuclear, for various applications. They are commonly used in superheaters, reheaters, steam generators, and turbine components that operate at high temperatures and are exposed to harsh environments.

4. Oil and gas industry: In the oil and gas industry, nickel alloy plates are employed in offshore and onshore exploration and production facilities. They are used in pipelines, valves, wellhead equipment, and processing units that require resistance to corrosion, high pressures, and extreme temperatures.

5. Aerospace and aviation: Nickel alloy plates find extensive use in the aerospace and aviation sectors. They are used in the manufacturing of aircraft engines, gas turbine components, and aerospace structural parts that require high-temperature strength, excellent fatigue resistance, and corrosion resistance.

6. Electronics industry: Nickel alloy plates are used in electronic components, particularly in connectors, lead frames, switches, and battery contacts. They offer good electrical conductivity, corrosion resistance, and compatibility with various soldering processes.

7. Medical industry: Nickel alloy plates are employed in medical devices and equipment, primarily due to their biocompatibility and resistance to corrosion in bodily fluids. They are used in implants, surgical instruments, orthopedic devices, and dental appliances.

8. Marine applications: Nickel alloy plates are suitable for marine environments due to their corrosion resistance to seawater and atmospheric conditions. They are used in shipbuilding, offshore platforms, and desalination plants.

It’s important to note that there are various types of nickel alloys available, such as Monel, Inconel, Hastelloy, and Nickel-Chromium alloys, each with different compositions and properties suited for specific applications. The selection of the appropriate nickel alloy will depend on the required corrosion resistance, temperature range, strength, and other specific needs of the application.