Nickel Alloy Coil

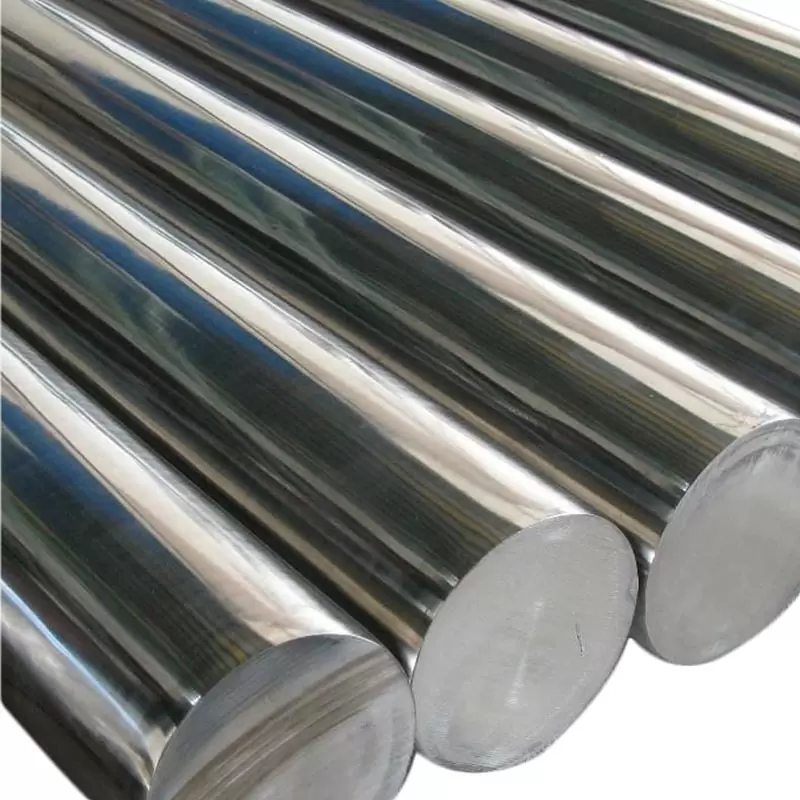

Nickel alloy coils are utilized in various industries for their exceptional properties. These coils are composed of nickel-based alloys that offer high corrosion resistance, stability at high temperatures, and excellent mechanical strength.

Request A Quote?

Product Details

Nickel alloy coils are utilized in various industries for their exceptional properties. These coils are composed of nickel-based alloys that offer high corrosion resistance, stability at high temperatures, and excellent mechanical strength.

Alloy Steel Description

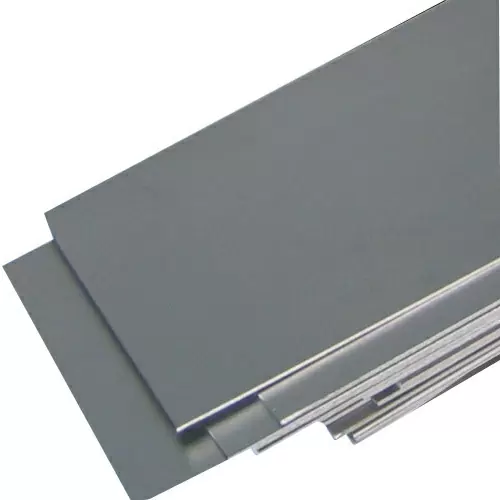

| Product Name | Nickel Coil |

| Type | Coil |

| Thickness | 0.3-20mm |

| Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Standard | ASTM,JIS, AISI, GB, DIN, EN |

| Surface | BA,2B,NO.1,NO.4,4K,HL,8K |

| Certification | ISO, SGS |

| Technique | Cold Rolled, Hot Rolled |

| Edge | Mill Edge Slit Edge |

| Quality | SGS Inspection |

| Price Term | CIF CFR FOB EX-WORK |

| Payment Terms | T/T L/C and Western Union etc |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

Chemical Properties of Frequently-used Stainless Steel Material Grade

| MATERIALS | GB | ASME/ASTM | DIN | JIS | SPECIFIC GRAVITY g/cm3 | CONTENT |

| NICKEL | N4 | N02201 | 2.4068 | NLC | 8.9 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.10C |

| NICKEL | N6 | N02200 | 2.4066 | NNC | 8.9 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.10C |

| NICKEL | N02270 | 2.4050 | 8.9 | 99.9Ni-0.02Fe-0.001Mn-0.002Si-0.005Cu-0.01C |

They find applications in aerospace, chemical processing, power generation, oil and gas, and medical industries.

In the aerospace industry, nickel alloy coils are crucial components in gas turbine engines, aircraft exhaust systems, and hydraulic and fuel systems. They withstand high temperatures and stress conditions and exhibit corrosion resistance.

Chemical processing industries employ nickel alloy coils in reactors, heat exchangers, and piping systems. These coils handle corrosive and high-temperature environments, ensuring reliable performance in chemical production.

Power generation facilities, including nuclear, fossil fuel, and renewable energy plants, utilize nickel alloy coils in heat exchangers, condensers, and steam generators. Their corrosion and creep resistance make them suitable for high-temperature environments.

The oil and gas industry relies on nickel alloy coils for equipment such as valves, pumps, and heat exchangers. These coils offer corrosion resistance, even in harsh environments with saltwater, acidic gases, and hydrocarbon compounds.

In the medical field, nickel alloy coils are used in implantable devices, dental instruments, and medical gas systems. They possess biocompatibility and resistance to body fluids, ensuring reliable and long-lasting medical equipment.

In short, nickel alloy coils are versatile components with applications across industries. Their corrosion resistance, high-temperature stability, and mechanical strength contribute to the efficiency and reliability of systems in aerospace, chemical processing, power generation, oil and gas, and medical sectors.