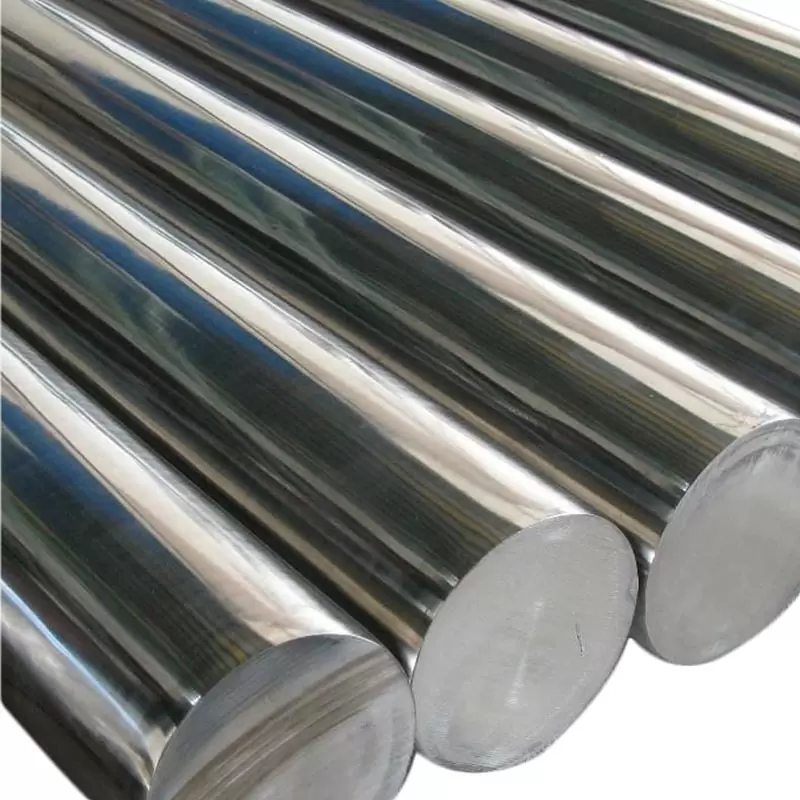

Nickel Alloy Bar

Nickel alloy bars are essential components used in various industries for their excellent mechanical properties, corrosion resistance, and thermal stability. These bars are made from nickel-based alloys that incorporate other elements to enhance their performance in specific applications.

Request A Quote?

Product Details

Nickel alloy bars are essential components used in various industries for their excellent mechanical properties, corrosion resistance, and thermal stability. These bars are made from nickel-based alloys that incorporate other elements to enhance their performance in specific applications.

Alloy Steel Description

| Product Name | Nickel Bar |

| Type | Bar |

| Outer Diameter | 4-600mm (3/8"-25") |

| Length | 40-400mm,2000mm, 2500mm, 3000mm, 5800mm, 6000mm,12000mm, etc |

| Standard | ASTM,JIS, AISI, GB, DIN, EN |

| Surface | BA,2B,NO.1,NO.4,4K,HL,8K |

| Certification | ISO, SGS,BV |

| Technique | Forging and cold drawing |

| Edge | Mill Edge Slit Edge |

| Quality | SGS Inspection |

| Price Term | CIF CFR FOB EX-WORK |

| Payment Terms | T/T L/C and Western Union etc |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

Chemical Properties of Frequently-used Stainless Steel Material Grade

| MATERIALS | GB | ASME/ASTM | DIN | JIS | SPECIFIC GRAVITY g/cm3 | CONTENT |

| NICKEL | N4 | N02201 | 2.4068 | NLC | 8.9 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.10C |

| NICKEL | N6 | N02200 | 2.4066 | NNC | 8.9 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.10C |

| NICKEL | N02270 | 2.4050 | 8.9 | 99.9Ni-0.02Fe-0.001Mn-0.002Si-0.005Cu-0.01C |

With their unique characteristics, nickel alloy bars find extensive usage in fields such as aerospace, oil and gas, chemical processing, power generation, and marine industries.

One of the main advantages of nickel alloy bars is their exceptional corrosion resistance. Nickel, as the primary component, provides excellent resistance to both general and localized corrosion, making these bars suitable for use in aggressive environments, such as chemical processing plants, offshore oil platforms, and marine applications. The corrosion resistance of nickel alloy bars ensures the longevity and reliability of critical components.

Nickel alloy bars are extensively utilized in the aerospace industry, where they play a vital role in various applications. These bars are used in the manufacturing of aircraft engine components, landing gear, and structural elements. The high strength and fatigue resistance of nickel alloy bars make them ideal for withstanding the demanding conditions of the aerospace environment. Additionally, their thermal stability enables them to maintain their mechanical properties even at elevated temperatures.

In the oil and gas industry, nickel alloy bars are employed in exploration, extraction, refining, and transportation processes. These bars are utilized in equipment such as pumps, valves, and tubing systems. The corrosion and erosion resistance of nickel alloy bars make them well-suited for harsh oil and gas environments, where they can withstand exposure to corrosive fluids, high pressures, and extreme temperatures.

Chemical processing plants rely on nickel alloy bars for critical applications in reactors, heat exchangers, and piping systems. The corrosion resistance of these bars is crucial in handling corrosive and high-temperature chemical environments. Their mechanical strength and resistance to stress corrosion cracking ensure the integrity and longevity of equipment, reducing downtime and maintenance costs.

Nickel alloy bars also find applications in power generation facilities, including fossil fuel, nuclear, and renewable energy plants. These bars are employed in steam turbines, heat exchangers, and other components subjected to high temperatures and corrosive environments. The thermal stability and corrosion resistance of nickel alloy bars contribute to the efficient and reliable operation of power generation systems.

Furthermore, nickel alloy bars are utilized in marine applications where they are exposed to seawater and aggressive marine environments. These bars are used in shipbuilding, offshore platforms, and other marine equipment, thanks to their corrosion resistance and strength. They can withstand the corrosive effects of saltwater, preventing the degradation of components and ensuring the safety and reliability of marine structures.

In summary, nickel alloy bars are versatile components with excellent mechanical properties and corrosion resistance. They find extensive applications in aerospace, oil and gas, chemical processing, power generation, and marine industries. These bars provide the necessary strength, corrosion resistance, and thermal stability required for critical applications in demanding environments. The reliability and longevity of nickel alloy bars contribute to the efficiency and performance of various systems and equipment.