Titanium Alloy Collection

Titanium alloy have a wide scope of use across various industries due to their exceptional properties.Our titanium coils, sheets, strip, plates, bars, rounds, squares, hexagon tubing and pipes are consistent with EN, DIN, ASTM, AMS and Mill Standards.

Request A Quote?

Product Details

Titanium alloy have a wide scope of use across various industries due to their exceptional properties.Our titanium coils, sheets, strip, plates, bars, rounds, squares, hexagon tubing and pipes are consistent with EN, DIN, ASTM, AMS and Mill Standards.

Titanium seamless tubes

| Standard | Available Material | Size |

| ASME / ASTM SB/B338, B337, B861, B862 AMS 4943, 4944, 4945 |

GR.1, GR.2, GR.3, GR.4, GR.7, GR.9, GR.12 | 1~114 x 0.3~8 x 18000mm max. |

| Tubes are subject to 100% ultrasonic testing, flatten & flaring test | ||

Titanium Bars

| Produce standard | Available Material | Size |

| ASTM B348, B381, F67, F136, Mil-T 9047 AMS4928, 4919 |

GR.1, GR.2, GR.3, GR.4, GR.5, GR.9, GR.12, 6A1-4V Eli, Ti-6-2-4-2 | Dia 5~300 x 6000mm max. |

| Bars are subject to 100% ultrasonic testing as per AMS2631 ClassA1, Class B | ||

Titanium Sheet & Plate & Coil

| Produce standard | Available Material | Size | |||

| ASME / ASTMSB / B265 / F136 / AMS4911, 4919, Mil-T-9046 | GR.1, GR.2, GR.3, GR.4, GR.5, GR.7, GR.9, GR.12, Ti-6242 | Cold rolled sheet: 0.4~5 x 1000 max x 2400mm max | Hot rolled plate: 5~80 x 3000 max x 6000mm max | Cold rolled coil: 0.4~3 x 1350 x coil, coil weight: 3~5 mt | Hot rolled coil: 3~12 x 1500 x coil |

Titanium Disk & Ring

| Standard | Available Material | Size | |

| ASTM B348, B381 AMS4928 | GR.1, GR.2, GR.3, GR.4, GR.5, GR.7, GR.12, 6Al-4V Eli | Disk: High 35~110mm x OD150~700mm | Ring: High 10~700mm x OD50~3000mm x ID30~2900mm |

Titanium Wires

| Standard | Available Material | Size |

| AWS A5, 16, AMS ISO5832 | GR.1, GR.2, GR.3, GR.4, GR.5, GR.7, GR.9, GR.12, GR23 | Dia. 0.05~7.0mm x coil |

Titanium Ingots

| Available Material | Size |

| GR.1, GR.2, GR.5, GR.7, GR.9, GR.12 | Dia. to 650mm |

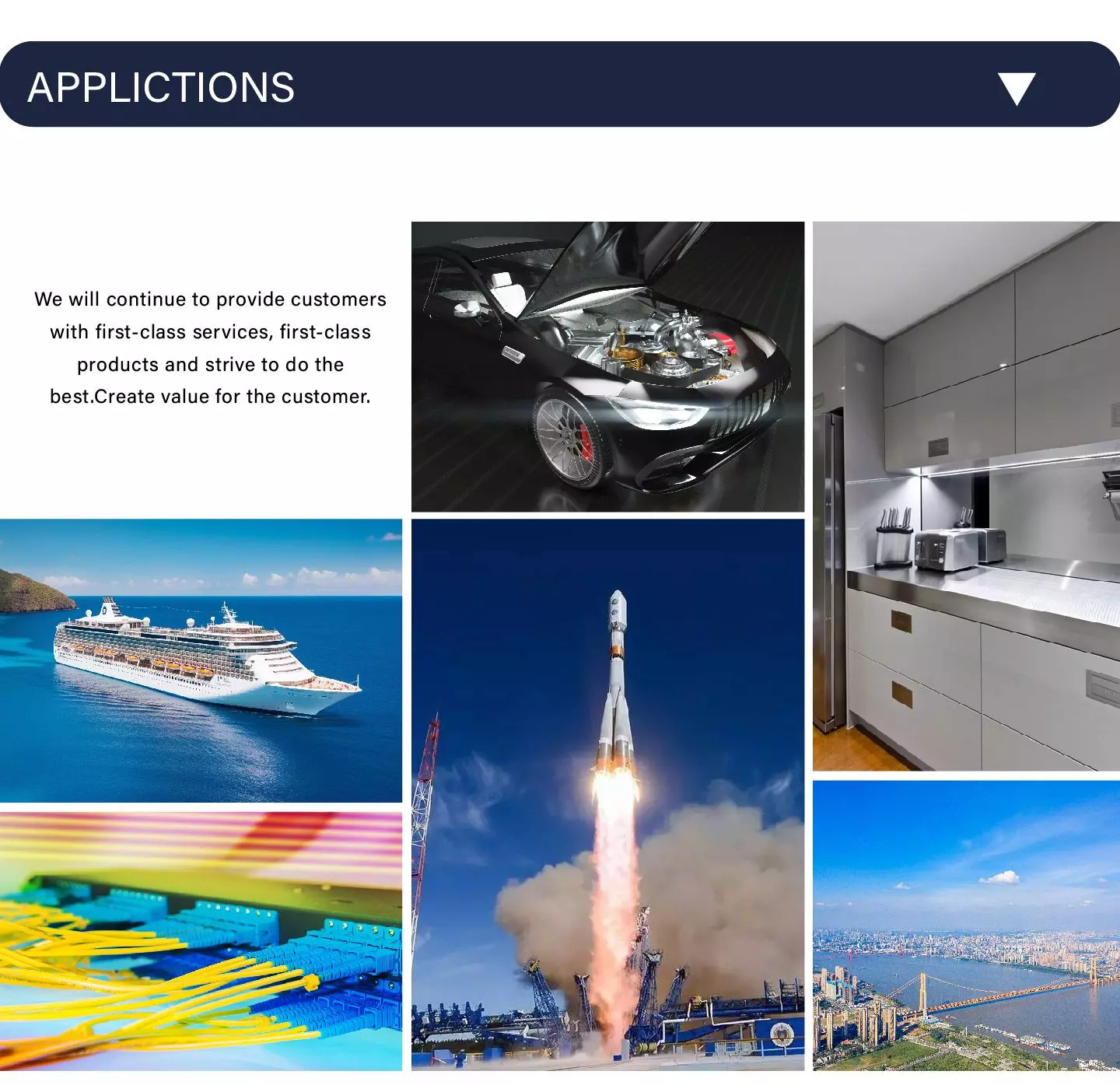

Here are some common applications:

1. Aerospace Industry: Titanium alloy plates are extensively used in the aerospace industry for manufacturing aircraft components like structural supports, landing gear, engine components, and airframe skins. Titanium’s high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures make it an ideal material for aircraft applications.

2. Chemical Processing: Titanium alloy plates are resistant to corrosion by most chemicals, including chlorides, sulfates, and organic compounds. They are commonly used in chemical processing plants for equipment like heat exchangers, reactors, and tanks, where they come into contact with corrosive substances.

3. Medical Field: Titanium alloy plates are biocompatible, meaning they are well-tolerated by the human body. They find extensive use in the medical field for orthopedic implants such as joint replacements (hips, knees), bone plates, screws, and dental implants.

4. Marine Industry: The marine environment is highly corrosive due to saltwater exposure. Titanium alloy plates are resistant to corrosion in seawater, making them suitable for marine applications, including ship hulls, propeller shafts, heat exchangers, and valves.

5. Automotive Industry: Titanium alloy plates are increasingly being used in the automotive industry due to their lightweight nature, high strength, and corrosion resistance. They are utilized in the manufacturing of exhaust systems, engine components, suspension systems, and other performance-oriented parts.

6. Sports and Recreation: Titanium alloy plates are used in sports equipment, such as bicycle frames, golf club heads, tennis rackets, and camping gear, due to their lightweight and high strength properties.

7. Industrial Applications: Titanium alloy plates find various industrial applications, including chemical plants, power generation, desalination plants, and oil and gas industry. They are utilized for heat exchangers, pressure vessels, pipelines, and offshore platforms.

It is important to note that the specific grade and composition of the titanium alloy will determine its suitability for a particular application.