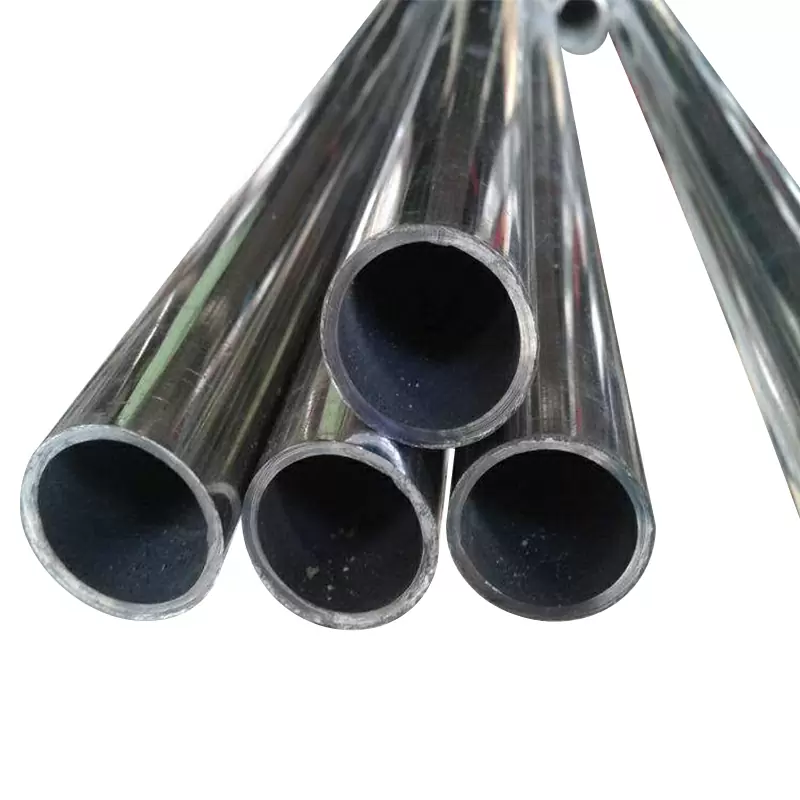

Hastelloy Alloy Wire

Hastelloy alloy wire is a highly versatile and corrosion-resistant wire that is widely used in numerous industries for its exceptional performance in demanding environments.

Request A Quote?

Product Details

Hastelloy alloy wire is a highly versatile and corrosion-resistant wire that is widely used in numerous industries for its exceptional performance in demanding environments.

Alloy Steel Description

| Product Name | Hastelloy Wire |

| Type | Wire |

| Diameter | 0.1-5.0mm |

| Length | c |

| Standard | ASTM,JIS, AISI, GB, DIN, EN |

| Surface | BA,2B,NO.1,8K |

| Certification | ISO, SGS |

| Price Term | CIF CFR FOB EX-WORK |

| Payment Terms | T/T L/C and Western Union etc |

Chemical Properties of Frequently-used

| SEQUENCE | DIN/EN | UNS NO | GENERIC TERM | INGREDIENT |

| 1 | 2.4819 | N10276 | Hastelloy C-276 | 57Ni-16Mo-16Cr-5Fe-4W-2.5Co-1Mn-0.35V-0.08Si-0.01C |

| 2 | 2.4610 | N06455 | Hastelloy C-4 | 65Ni-16Cr-16Mo-0.7Ti-3Fe-2Co-1Mn-0.08Si-0.01C |

| 3 | 2.4602 | N06022 | Hastelloy C-22 | 56Ni-22Cr-13Mo-3Fe-2.5Co-0.5Mn-0.35V-0.08Si-0.01C |

| 4 | 2.4675 | N06200 | Hastelloy C-2000 | 59Ni-23Cr-16Mo-1.6Cu-0.08Si-0.01C |

| 5 | 2.4665 | N06002 | Hastelloy X | 47Ni-22Cr-18Fe-9Mo-1.5Co-0.6W-0.1C-1mn-1Si-0.008B |

| 6 | 2.4617 | N10665 | Hastelloy B-2 | 69Ni-28Mo-0.5Cr-1.8Fe-3W-1.0Co-1.0Mn-0.01C |

| 7 | 2.4660 | N10675 | Hastelloy B-3 | 65Ni-28.5Mo-1.5Cr-1.5Fe-3W-3Co-3Mn-0.01C |

| 8 | N06030 | Hastelloy G-30 | 43Ni-30Cr-15Fe-5.5Mo-2.5W-5Co-2Cu-1.5Mn-0.03C | |

| 9 | N06035 | Hastelloy G-35 | 58Ni-33Cr-8Mo-2Fe-0.6Si-0.3Cu-0.03C |

It belongs to the Hastelloy family of alloys, known for their excellent resistance to corrosion, high-temperature stability, and superior mechanical properties.

Hastelloy alloy wire is primarily composed of nickel, chromium, molybdenum, and small amounts of other elements such as iron, cobalt, and tungsten. This unique combination of elements gives Hastelloy its remarkable resistance to corrosion, making it highly sought after in industries such as chemical processing, petrochemical, and power generation.

One of the most significant advantages of Hastelloy alloy wire is its exceptional resistance to corrosion. It exhibits excellent resistance to a wide range of corrosive media, including acids, alkalis, and chlorides. This resistance is maintained even in harsh and aggressive environments, making Hastelloy wire suitable for applications that handle corrosive chemicals, gases, and liquids.

In addition to its corrosion resistance, Hastelloy alloy wire offers superior mechanical properties. It has excellent strength, ductility, and toughness, making it highly durable and reliable in demanding conditions. Hastelloy wire can withstand high temperatures and pressures, making it ideal for applications where extreme conditions exist.

Another notable feature of Hastelloy alloy wire is its versatility in various fabrication processes. It can be easily drawn, annealed, and shaped into different forms such as round, square, or flat wire. Hastelloy wire can also be welded, allowing for the creation of complex structures and components. This flexibility in fabrication makes Hastelloy wire a preferred choice for a wide range of applications.

Hastelloy alloy wire finds applications in numerous industries. In the chemical processing industry, it is used in the production of reactors, heat exchangers, and catalysts that handle corrosive chemicals. In the aerospace industry, Hastelloy wire is employed in wiring harnesses, electrical connectors, and aircraft engine components, benefiting from its high-temperature stability and mechanical strength.

Moreover, Hastelloy alloy wire has significant applications in the pharmaceutical and medical fields. It is used in the manufacturing of medical devices, surgical instruments, and implants due to its biocompatibility and resistance to corrosion in bodily fluids. The wire’s superior strength and resistance to wear also make it suitable for applications in the automotive and electronics industries.

In summary, Hastelloy alloy wire is a versatile and corrosion-resistant wire used across various industries. Its exceptional resistance to corrosion, high-temperature stability, and mechanical properties make it an excellent choice for demanding environments. Whether it’s in chemical processing, aerospace, medical, or other industries, Hastelloy alloy wire provides a reliable and high-performance solution to challenges posed by corrosive and severe operating conditions.