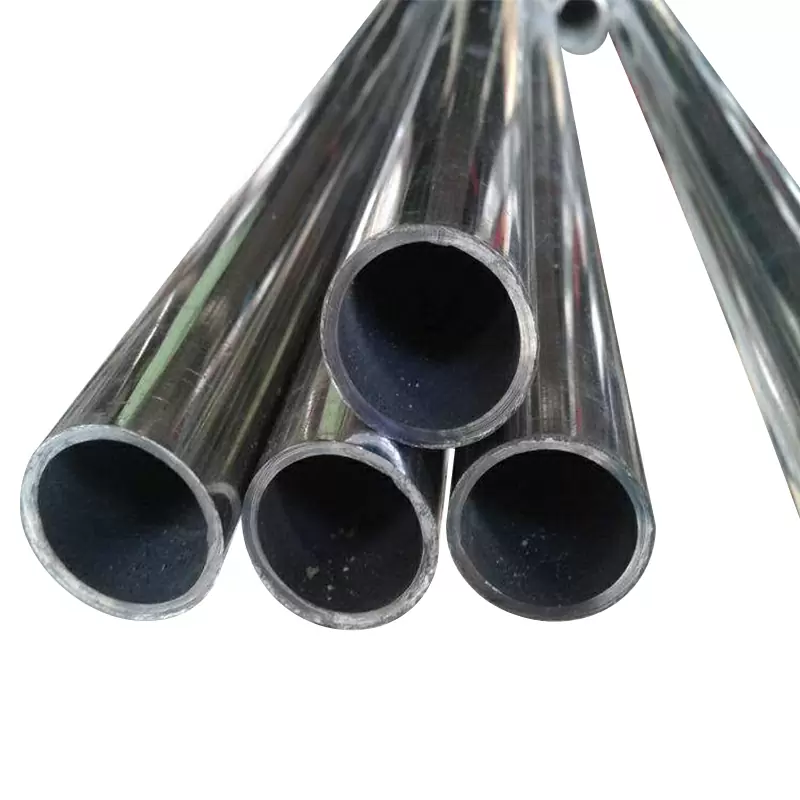

Hastelloy Alloy Bar

Hastelloy alloy bar is a type of high-performance, corrosion-resistant bar that is widely used in industries that require exceptional resistance to aggressive environments.

Request A Quote?

Product Details

Hastelloy alloy bar is a type of high-performance, corrosion-resistant bar that is widely used in industries that require exceptional resistance to aggressive environments.

Alloy Steel Description

| Product Name | Hastelloy Bar |

| Type | Bar |

| Outer Diameter | 4-600mm (3/8"-25") |

| Length | 40-400mm,2000mm, 2500mm, 3000mm, 5800mm, 6000mm,12000mm, etc |

| Standard | ASTM,JIS, AISI, GB, DIN, EN |

| Surface | BA,2B,NO.1,NO.4,4K,HL,8K |

| Certification | ISO, SGS,BV |

| Technique | Forging and cold drawing |

| Edge | Mill Edge Slit Edge |

| Quality | SGS Inspection |

| Price Term | CIF CFR FOB EX-WORK |

| Payment Terms | T/T L/C and Western Union etc |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

Chemical Properties of Frequently-used

| SEQUENCE | DIN/EN | UNS NO | GENERIC TERM | INGREDIENT |

| 1 | 2.4819 | N10276 | Hastelloy C-276 | 57Ni-16Mo-16Cr-5Fe-4W-2.5Co-1Mn-0.35V-0.08Si-0.01C |

| 2 | 2.4610 | N06455 | Hastelloy C-4 | 65Ni-16Cr-16Mo-0.7Ti-3Fe-2Co-1Mn-0.08Si-0.01C |

| 3 | 2.4602 | N06022 | Hastelloy C-22 | 56Ni-22Cr-13Mo-3Fe-2.5Co-0.5Mn-0.35V-0.08Si-0.01C |

| 4 | 2.4675 | N06200 | Hastelloy C-2000 | 59Ni-23Cr-16Mo-1.6Cu-0.08Si-0.01C |

| 5 | 2.4665 | N06002 | Hastelloy X | 47Ni-22Cr-18Fe-9Mo-1.5Co-0.6W-0.1C-1mn-1Si-0.008B |

| 6 | 2.4617 | N10665 | Hastelloy B-2 | 69Ni-28Mo-0.5Cr-1.8Fe-3W-1.0Co-1.0Mn-0.01C |

| 7 | 2.4660 | N10675 | Hastelloy B-3 | 65Ni-28.5Mo-1.5Cr-1.5Fe-3W-3Co-3Mn-0.01C |

| 8 | N06030 | Hastelloy G-30 | 43Ni-30Cr-15Fe-5.5Mo-2.5W-5Co-2Cu-1.5Mn-0.03C | |

| 9 | N06035 | Hastelloy G-35 | 58Ni-33Cr-8Mo-2Fe-0.6Si-0.3Cu-0.03C |

It belongs to the Hastelloy family of alloys, known for their excellent corrosion resistance, high-temperature stability, and superior mechanical properties.

Hastelloy alloy bars are primarily composed of nickel, chromium, molybdenum, and a small percentage of other elements such as iron, cobalt, and tungsten. This unique combination of elements gives Hastelloy its exceptional resistance to corrosion, making it highly sought after in industries such as chemical processing, petrochemical, and offshore oil and gas.

One of the key advantages of Hastelloy alloy bars is their outstanding resistance to a wide range of corrosive media. They exhibit excellent resistance to acids, alkalis, and chlorides, making them suitable for handling aggressive chemicals and environments. This corrosion resistance is maintained even at elevated temperatures, which is crucial in applications where high-temperature exposure is common.

Moreover, Hastelloy alloy bars offer excellent mechanical properties, including high strength and toughness. They can withstand extreme temperatures and pressures, making them ideal for use in challenging conditions. This exceptional strength allows Hastelloy bars to be used in various demanding applications, including pressure vessels, heat exchangers, valves, and other critical components.

In addition to corrosion resistance and mechanical strength, Hastelloy alloy bars also exhibit good fabricability. They can be easily machined, formed, and welded, allowing for customization and ease of manufacturing. This flexibility in fabrication ensures that Hastelloy bars can be tailored to specific design requirements, making them suitable for a wide range of applications.

Hastelloy alloy bars find applications in numerous industries. In the chemical processing industry, they are used in reactors, piping systems, and vessels that handle corrosive chemicals. In the aerospace industry, Hastelloy bars are utilized in turbine engines, exhaust systems, and other high-temperature applications. They are also employed in the oil and gas industry for offshore platforms, pipelines, and downhole tools, where resistance to harsh environments is essential.

Furthermore, Hastelloy alloy bars are commonly used in the pharmaceutical industry, power generation plants, and desalination facilities, among others. Their exceptional corrosion resistance and mechanical properties make them ideal for applications where reliability and longevity are paramount.

In summary, Hastelloy alloy bars are high-performance, corrosion-resistant bars used in various industries. Their exceptional resistance to corrosion, high-temperature stability, and mechanical strength make them ideal for demanding applications. Whether it’s in chemical processing, aerospace, oil and gas, or other industries, Hastelloy alloy bars provide a reliable and durable solution to challenges posed by aggressive environments.