ASTM 444 - EN 1.4521

ASTM 444 - EN 1.4521 is an 18% chromium stainless steel which is nickel-free, has a stabilized molybdenum alloy, is capable of use in corrosive settings, and offers good welding and high-temperature properties. Its ferritic microstructure endows it with resistance to chloride-induced stress corrosion cracking.

Request A Quote?

Product Details

ASTM 444 - EN 1.4521 is an 18% chromium stainless steel which is nickel-free, has a stabilized molybdenum alloy, is capable of use in corrosive settings, and offers good welding and high-temperature properties. Its ferritic microstructure endows it with resistance to chloride-induced stress corrosion cracking.

| Chemical Composition | 17.0 – 20.0Cr, 1.8 |

| Physical Property | • Density: 7.7 g/cm³ • Electrical resistance: 0.60 μΩ·m • Thermal conductivity: 23 W/(m·K) • Specific heat: 460 J/(kg·K) • Young's modulus: 220 GPa • 0.2% Yield stress: 275 MPa, min |

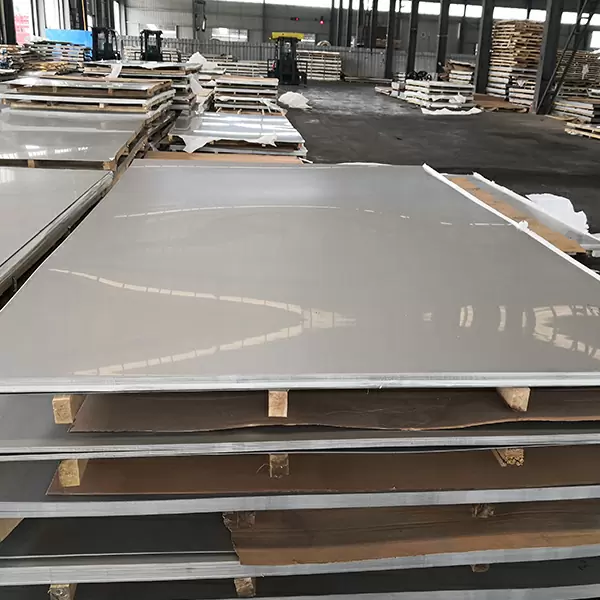

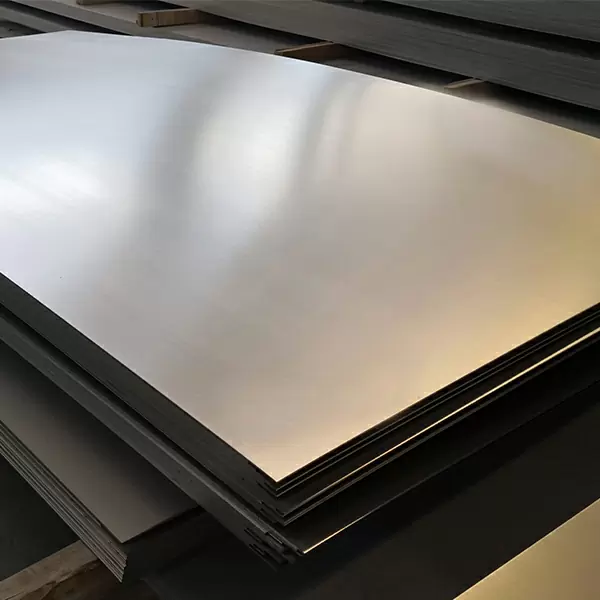

| Stock & Dimensions | Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs. • Bar: 0.5~600mm Diameter • Coil: 0.5~150mm Thick • Plate: 0.5~200mm Thick • Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick • Available in specific sizes |

| Product Forms | We provide you with a variety of product forms, including but not limited to: • Bar/Rod • Pipe/Tube • Coil/Strip • Plate/Sheet/Circle • Wire • Fitting (Flange, Elbow, Tee...) • Customize |

Essential details

AISI 444 is a low carbon, dual stabilised, molybdenum containing ferritic stainless steel with good ductility, toughness and resistance to sensitisation, even in the welds. With 18% chromium and 2% molybdenum, the steel has good pitting resistance and crevice corrosion resistance, similar to 316 and good general corrosion resistance and oxidation resistance, similar to 316 in most environments. Being a ferritic stainless steel, EN 1.4521 is not susceptible to Stress Corrosion Cracking. Annealed UNS S44401 is ductile and can be formed using a wide range of roll forming or mild stretch bending operations as well as the more common drawing and bending operations. It does not harden excessively during cold working.

Application:

- Heat exchangers

- Acid and nitrogen oxide pipelines

- Acid storage tanks

- Acid transport tanks

- Dairy, fruit and vegetable and brewery industries

- Textile industry

- Household appliances