ASTM 304L - EN 1.4306

As a low-carbon 304 steel, its corrosion resistance is equal to 304's under regular conditions; moreover, it boasts exemplary resistance to intergranular corrosion when welded or after undergoing stress relief, and can maintain good resistance without heat treatment, in a temperature range from -196℃ to 800℃.

Request A Quote?

Product Details

As a low-carbon 304 steel, its corrosion resistance is equal to 304's under regular conditions; moreover, it boasts exemplary resistance to intergranular corrosion when welded or after undergoing stress relief, and can maintain good resistance without heat treatment, in a temperature range from -196℃ to 800℃.

| Chemical Composition | 0.02C-18.2Cr-10.1Ni |

| Physical Property | • Density: 7.9 g/cm³ • Tensile Strength: 580 MPa • Yield Strength: 200 MPa • Modulus of Elasticity: 179 GPa • Thermal exp.at 100 ℃: 10-6/℃ • Thermal Conductivity: 15 W/m°C |

| Stock & Dimensions | Our warehouse has a large number of stock to provide you with a variety of products in different sizes,

and can also customize the size according to your needs. • Bar: 0.5~600mm Diameter • Coil: 0.5~150mm Thick • Plate: 0.5~200mm Thick • Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick • Available in specific sizes |

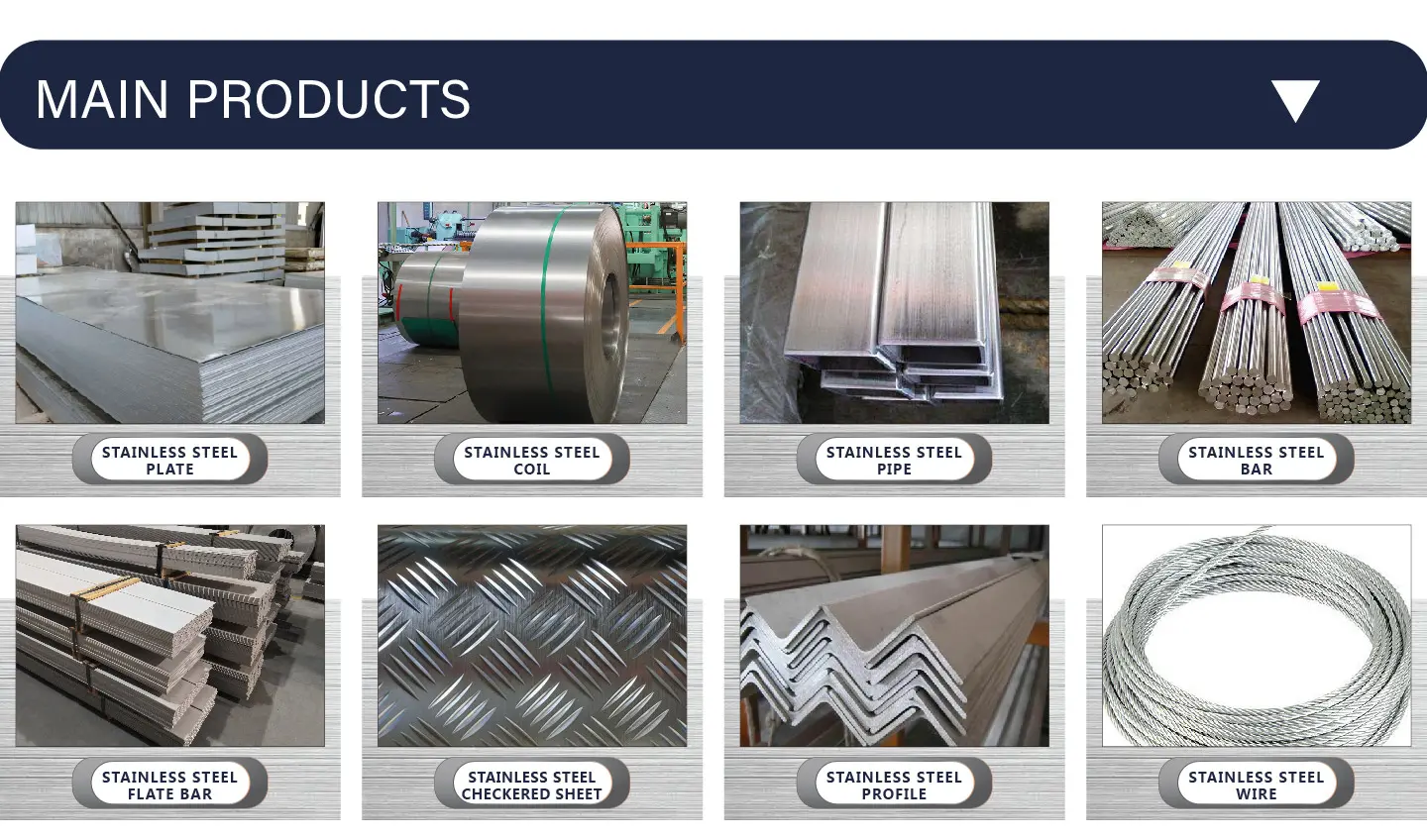

| Product Forms | We provide you with a variety of product forms, including but not limited to: • Bar/Rod • Pipe/Tube • Coil/Strip • Plate/Sheet/Circle • Wire • Fitting (Flange, Elbow, Tee...) • Customize |

Essential details

304L/4306 is a higher nickel alternative to 304L/4307 with improved formability and deep drawability.

304L/4306 is an austenitic stainless steel that belongs to the standard CrNi stainless steel family.

304L/4306 has the variant with 10.5 wt.% nickel for improved formability and low carbon content for improved resistance against intergranular corrosion after welding.

The austenitic CrNi standard grades are the most widely used group of stainless steels. Their well-balanced material properties make them suitable for the fabrication of many products.

304L/4306 is commonly available from many stainless steel stockists in manyproduct forms and dimensions. It can be supplied with a wide range of functional and aesthetic surface finishes.

Typical Applications

- Chemical and pharmaceutical plant equipment (mild to medium corrosive environments)

- Flanges and valves