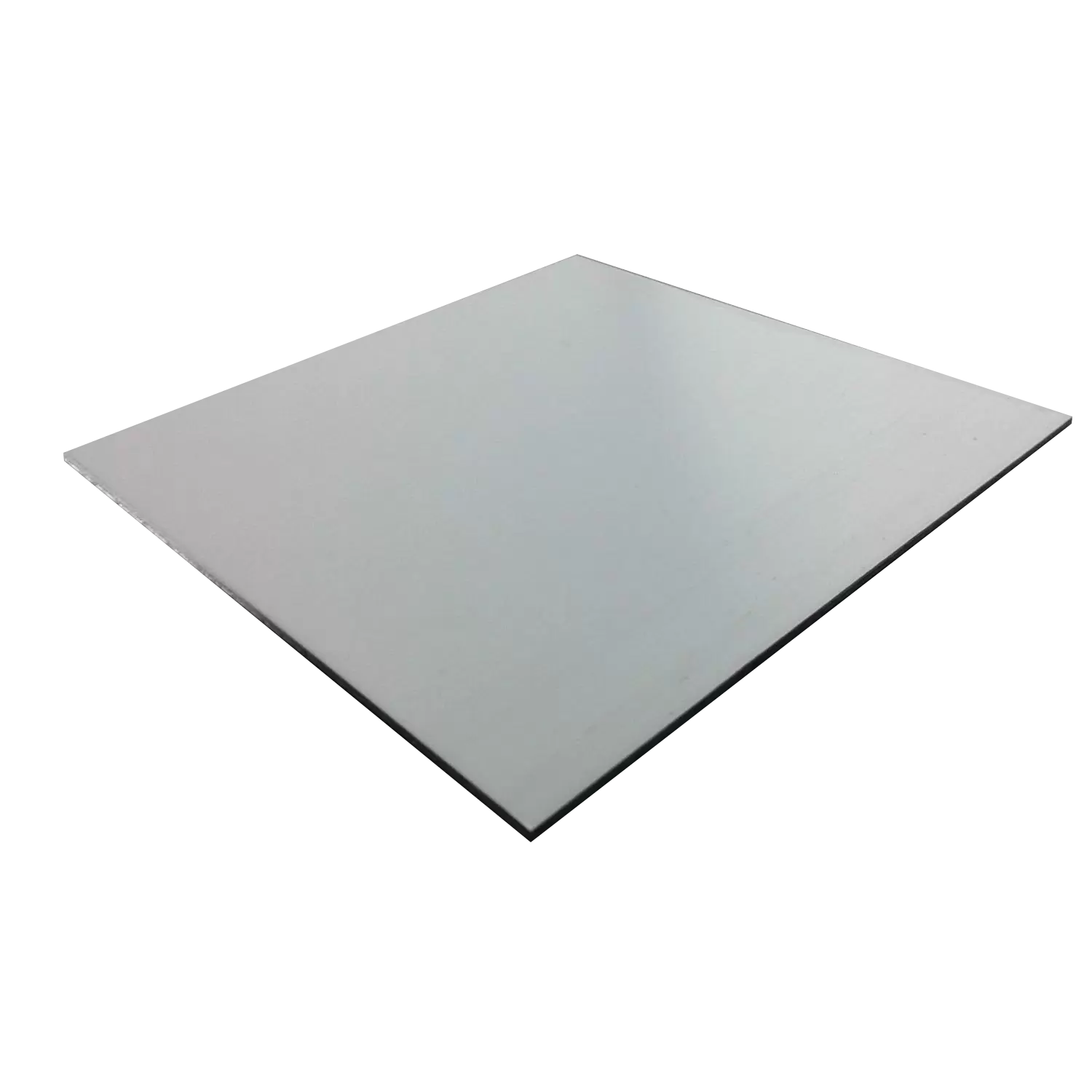

Inconel Alloy Plate

Inconel is a family of nickel-based superalloys known for their excellent high-temperature strength and corrosion resistance. Inconel alloy plates are widely used in various industries due to their unique properties.

Request A Quote?

Product Details

Inconel is a family of nickel-based superalloys known for their excellent high-temperature strength and corrosion resistance. Inconel alloy plates are widely used in various industries due to their unique properties.

Alloy Steel Description

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others:253Ma,254SMo,654SMo,F50(UNSS32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy : Alloy 20/28/31 | |

| Hastelloy:HastelloyB/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g | |

| Hastelloy B/UNS N10001, Hastelloy B-2/UNS N10665/DIN W. Nr. 2.4617, Hastelloy C, Hastelloy C-4/UNS N06455/DIN W. Nr. 2.4610, Hastelloy C22/UNS N06022/DIN W. Nr. 2.4602,Hastelloy C276/UNS N10276/DIN W. Nr. 2.4819, Hastelloy X/UNS N06002/DIN W. Nr. 2.4665 | |

| Haynes: Haynes 230/556/188 | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20 | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851,Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 | |

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60 | |

| Nimonic: Nimonic 75/80A/90/A263 | |

| Specification | Wire: 0.01-10mmStrip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mmPipe: φ6-273mm;δ1-30mm;Length 1000-8000mmSheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturingand combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

Chemical Properties of Frequently-used

| SEQUENCE | DIN/EN | UNS NO | GENERIC TERM | INGREDIENT |

| 1 | 2.4816 | N06600 | INCONEL Alloy 600 | 72Ni-151Cr-8Fr-0.2Cu-0.02C |

| 2 | 2.4851 | N06601 | INCONEL Alloy 601 | 60Ni-22Cr-1.2Al-0.02C |

| 3 | 2.4856 | N06625 | INCONEL Alloy 625 | 58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 4 | 2.4856 | N06626 | INCONEL Alloy 625LCF | 58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 5 | 2.4606 | N06686 | INCONEL Alloy 686 | 57Ni-21Cr-16Mo-4W-0.01C |

| 6 | 2.4642 | N06690 | INCONEL Alloy 690 | 58Ni-30Cr-9Fe-0.2Cu-0.02C |

| 7 | 2.4668 | N07718 | INCONEL Alloy 718 | 52Ni-19Cr-5Nb-3Mo-1Ti-0.6Al-0.02C |

| 8 | 2.4669 | N07750 | INCONEL Alloy 750 | 70Ni-15Cr-6Fe-2.5Ti-0.06Al-1Nb-0.02C |

Here are some common applications:

1. Aerospace and aviation: Inconel alloy plates are extensively used in aircraft and aerospace applications. They are utilized in gas turbine engine components, such as turbine blades, combustion chambers, and exhaust systems, where they can withstand high temperatures and corrosive environments.

2. Power generation: Inconel plates find use in power plants, including nuclear and gas turbine power plants. They are employed in critical components like steam turbine seals, boiler tubes, and heat exchangers, where they resist the effects of high temperatures and corrosive conditions.

3. Chemical processing: Inconel plates are suitable for chemical processing equipment exposed to corrosive chemicals, acids, and high-temperature environments. They are used in reactors, valves, piping systems, and heat exchangers.

4. Oil and gas industry: Inconel plates are utilized in oil and gas extraction and processing equipment, including offshore platforms, pipelines, and downhole tools. They can resist corrosion, high pressures, and harsh environments encountered in oil and gas exploration.

5. Automotive industry: Inconel alloy plates are employed in high-performance automotive applications. They can be found in exhaust systems, turbochargers, and other engine components that require resistance to high temperatures and corrosion.

6. Medical and chemical laboratories: Inconel plates are used in laboratory equipment and instruments where resistance to chemicals, heat, and corrosion is essential, such as in chemical reactors, autoclaves, and analytical instruments.

7. Marine applications: Inconel plates are suitable for marine environments due to their high resistance to corrosion from seawater and marine atmospheres. They are used in marine exhaust systems, propeller shafts, and seawater desalination plants.

It’s worth noting that there are different grades of Inconel alloys available, such as Inconel 600. Inconel 625. and Inconel 718. each with specific compositions and properties tailored for different applications. The choice of alloy will depend on the specific requirements of the intended use.