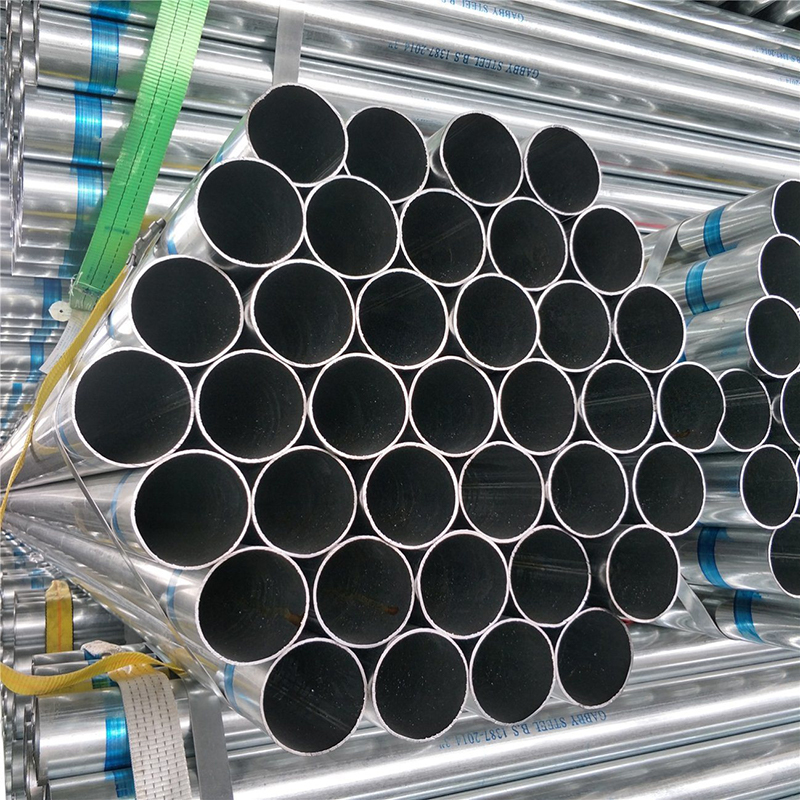

ST35 Galvanized pipe

The ST 35 Steel Grade Pipe has minimum 480MPa tensile strength and 315MPa yield strength under normal conditions. The carbon steel has high toughness and is used for high wear and tear applications. There are different shapes of the pipes such as the Carbon Steel DIN 2391 ST35 Round Pipe and other shapes.

Request A Quote?

Product Details

The ST 35 Steel Grade Pipe has minimum 480MPa tensile strength and 315MPa yield strength under normal conditions. The carbon steel has high toughness and is used for high wear and tear applications. There are different shapes of the pipes such as the Carbon Steel DIN 2391 ST35 Round Pipe and other shapes. The geometrical shapes play an important role in some applications. The structural applications use the square pipes for their strength. The DIN 2391 ST35 Welded Pipe can be used for excessive welding applications. Welding is possible on this material with or without filler materials. The applications include the petroleum industries, oil and gas industries, chemical, food processing and power generation industries. The high wear and tear properties of the ST 35 Material come from the composition. The material has carbon, silicon, manganese, phosphorus and sulfur in it. Please feel free to contact us for more information on the DIN 2448 ST 35 grade pipes and their prices.

Galvanized Welded Pipe Parameter

| Standard | ASTM A53, BS1387-85, GB/T3091-08, DIN2440, JIS-G3444, EN10240, EN10255 etc. |

| Grade | Q195, Q215, Q235, Q345, S235JR, S275JR, STK400, STK500 etc. |

| Type & Zinc Coating | Hot dip galvanized steel pipe (zinc coating: 60g/m2-275g/m2) |

| Pre-painted galvanized steel pipe (zinc coating: 80g/m2-275g/m2) | |

| Outer Diameter | Round pipe: 17mm-273mm |

| Square pipe: 15mm x 15mm - 400mm x 400mm | |

| Rectangular pipe: 10mm x 20mm -200mm x 400mm | |

| Wall Thickness | Round pipe: 0.6mm-12mm |

| Square pipe: 0.6mm-20mm | |

| Rectangular pipe: 0.6mm-20mm | |

| Length | Length: 2m-5.8m/6m/12m ( We can adjust length according to your request) |

| Process | Cold Drawn Tube / Hot Rolled Tube |

| Testing Methods | Pressure test, Flaw detection, Eddy current testing, Hydrostatic testing or Ultrasonicexamination and also with chemical and physical property inspection |

| Third Party Inspection | SGS / BV / MTC etc. |

| Payment Terms | FOB 30%T/T,70% before shipment or CIF 30% pre-payment and the balance to be paid upon B/L (copy) |