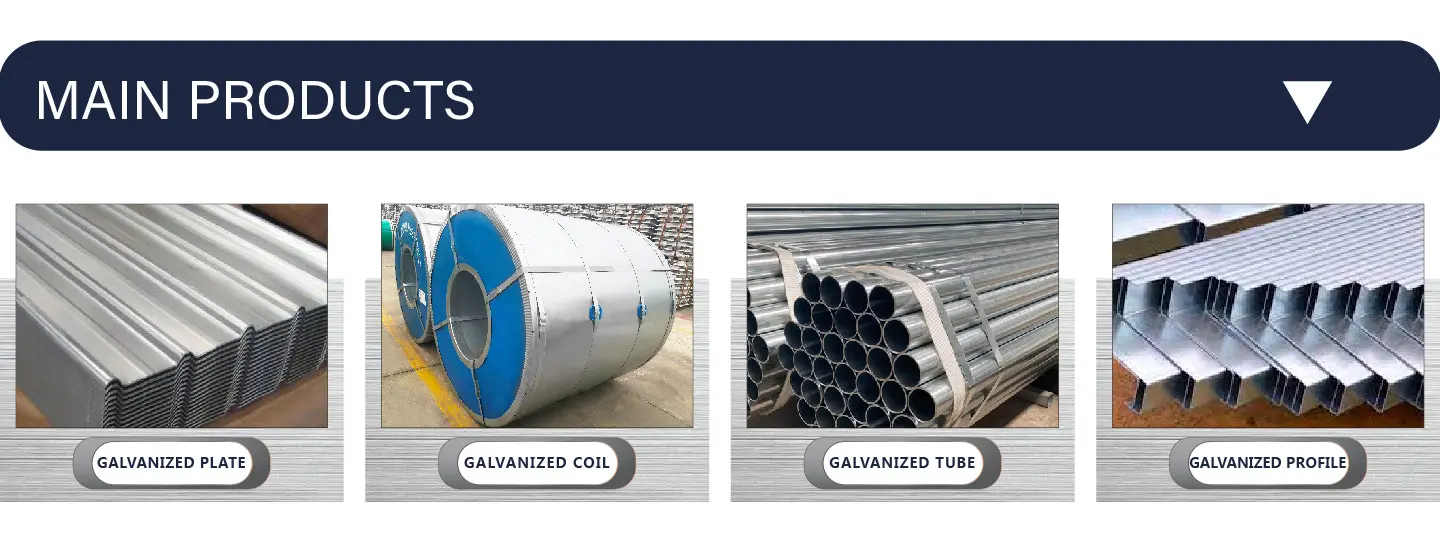

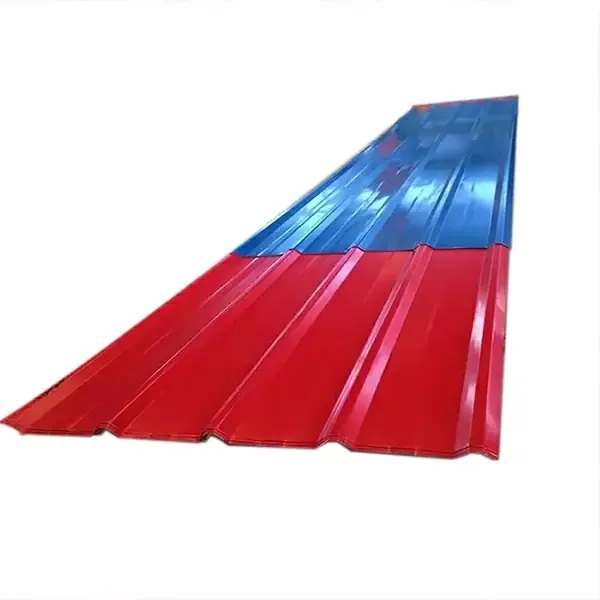

Gi Galvanized coated corrugated roofing sheet

Galvanized coated panels, also known as galvanized steel panels, have numerous uses in various industries. These panels are made from steel that has been coated with a layer of zinc through a process called galvanization. The zinc coating provides several benefits, including increased durability, corrosion resistance, and aesthetic appeal.

Request A Quote?

Product Details

Galvanized coated panels, also known as galvanized steel panels, have numerous uses in various industries. These panels are made from steel that has been coated with a layer of zinc through a process called galvanization. The zinc coating provides several benefits, including increased durability, corrosion resistance, and aesthetic appeal.

| Products name | Gi Galvanized coated corrugated roofing sheet |

| Thickness | 0.12-6.00mm,or as request. |

| Width | 650-930mm,600-1500mm or as request. |

| Length | 2m/3m/5m/5.8m/6m/8m/11.8m/ |

| Surface Structure | Normal spangle coating(NS),minimized spangle coating(MS),spangle-free(FS) |

| Advantages | 1.Reliable quality and negotiable price Large inventory, quick delivery 24 hours online, reply to your message within 3 minutes 2.A variety of materials A variety of surfaces Complete specifications Support samples 3.Customized processing, arbitrary cutting Large stock, factory direct supply |

| Type of Coating | Hot Dipped Galvanized Steel(HDGI)/Electro-Galvanised Steel(EGI) |

| Surface treatment | 1. Galvanized 2. PVC,Black and color painting 3. Transparent oil,anti-rust oil 4. According to clients requirement |

| Product Application | 1. Fence, greenhouse, door pipe,greenhouse 2. Low pressure liquid, water, gas, oil, line pipe 3. For both indoor and outdoor the building construction 4. Widely used in scaffolding construction which is much cheaper and convenient |

| Packing | Bundle, or with all kinds of colors PVC or as your requirements |

Product chemical component

| bse metal type | Grade | CHEMICAL COMPOSITION % | |||

| C | Si | Mn | P | ||

| Cold rolled steel sheet | DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | ≤0.10 | - | ≤0.50 | ≤0.035 |

| DC52D+Z (St04Z), DC52D+ZF | ≤0.08 | - | ≤0.45 | ≤0.030 | |

| DC53D+Z (St05Z), DC53D+ZF | ≤0.08 | - | ≤0.40 | ≤0.030 | |

| DC54D+Z (St06Z), DC54D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| DC56D+Z (St07Z), DC56D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| Hot rolled steel sheet | DD51D+Z (St01ZR, St02ZR) | ≤0.10 | - | ≤0.50 | ≤0.035 |

| DD54D+Z (St06ZR) | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

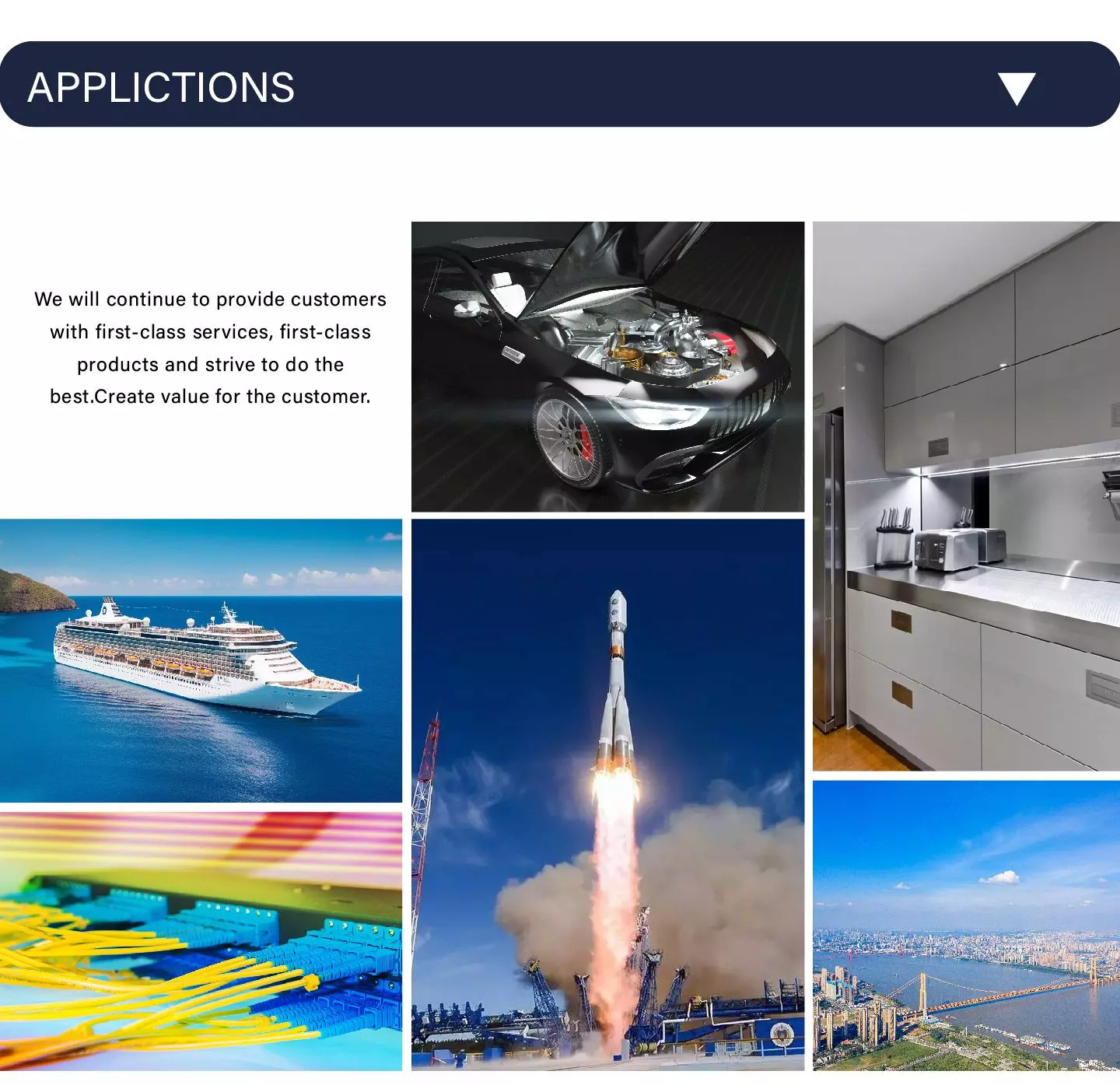

Here are some common uses of galvanized coated panels:

1. Construction: Galvanized coated panels are widely used in the construction industry. They are commonly used for roofing, siding, wall panels, and structural components in both residential and commercial buildings. The zinc coating protects the steel from rust and corrosion, ensuring longevity and structural integrity.

2. Agricultural Buildings: Galvanized coated panels are commonly used in agricultural structures such as barns, sheds, and poultry houses. They provide reliable protection against the harsh outdoor environment, including moisture, sunlight, and chemicals used in farming.

3. Fencing and Enclosures: Galvanized coated panels are popular for fencing applications. They are used for constructing sturdy and long-lasting fences, gates, and enclosures for residential, commercial, and industrial purposes. The zinc coating enhances their resistance to rust and corrosion, making them suitable for outdoor use.

4. Automotive Industry: Galvanized coated panels find applications in the automotive industry, particularly for manufacturing vehicle parts such as body panels, chassis components, and undercarriage parts. The zinc coating provides effective protection against road salt, moisture, and other environmental factors, extending the lifespan of these components.

5. HVAC and Ventilation Systems: Galvanized coated panels are commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems. They are used for manufacturing ductwork, air vents, and other components that require durability, corrosion resistance, and a clean, professional appearance.

6. Industrial Applications: Galvanized coated panels are utilized in various industrial applications where corrosion resistance is crucial. They are used for manufacturing storage tanks, containers, industrial shelving, and platforms, providing reliable protection against rust and chemical exposure.

7. Electrical Enclosures: Galvanized coated panels are suitable for electrical enclosures due to their durability and corrosion resistance. Enclosures made from galvanized coated panels protect electrical equipment, such as control panels and junction boxes, from moisture and environmental damage.

8. Decorative and Architectural Applications: Galvanized coated panels are often used in architectural design and decorative applications. They can be used for cladding building facades, interior wall panels, decorative screens, and signage.

The specific use of galvanized coated panels depends on the industry, application requirements, and the need for corrosion resistance and durability.