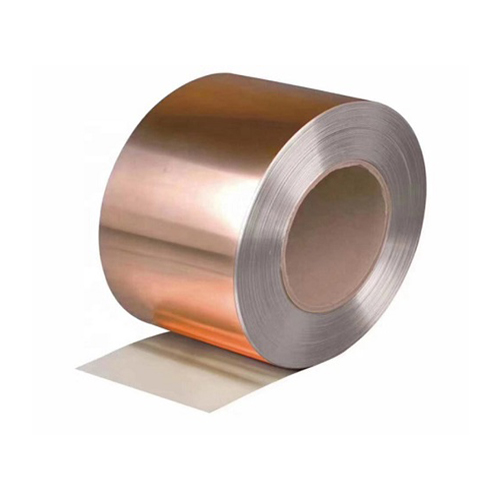

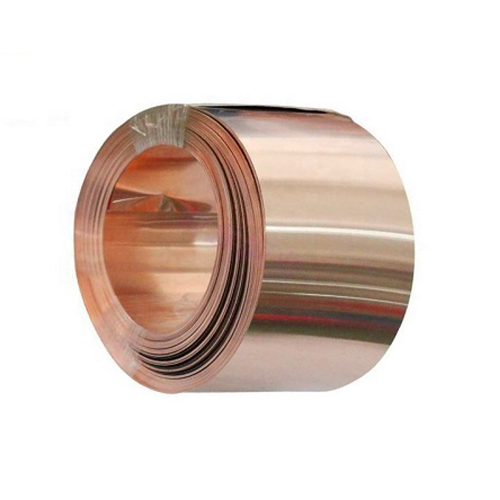

Phosphor Bronzes

Tin phosphor bronze has higher corrosion resistance, wear resistance, and does not spark when impacted. For medium-speed, heavy-duty bearings, the maximum working temperature is 250°C. It has the characteristics of self-aligning, insensitive to deflection, uniform bearing force and high bearing capacity, can bear radial load at the same time, self-lubricating and maintenance-free.

Request A Quote?

Product Details

Tin phosphor bronze has higher corrosion resistance, wear resistance, and does not spark when impacted. For medium-speed, heavy-duty bearings, the maximum working temperature is 250°C. It has the characteristics of self-aligning, insensitive to deflection, uniform bearing force and high bearing capacity, can bear radial load at the same time, self-lubricating and maintenance-free. Tin phosphor bronze is a kind of alloy copper, which has good electrical conductivity, is not easy to generate heat, ensures safety and has strong fatigue resistance. Tin phosphor bronze socket reed hard-wired electrical structure, no rivet connection or no friction contact, can ensure good contact, good elasticity, and smooth insertion and insertion. The alloy has excellent machinability and chip forming performance, and can quickly shorten the processing time of parts. As an intermediate alloy, phosphor bronze is widely used in copper casting, solder and other fields, and plays an important role in the development of the national economy.

| Products name | Phosphor Bronzes |

| Thickness | 0.3-120mm |

| Width | 2-2500mm |

| MOQ | Non |

| Length | C |

| Surface | mill,polished,bright,mirror,hair line,brush,checkered,antique,sand blast,etc |

| Standard | IOS,JIS,BS,DIN,ASTM |

| Delivery Time | 7-45Days |

| Packing | Standard Seaworthy Packing |

| Application | Automobile, electronics, wire and cable, photovoltaic manufacturing, home appliance manufacturing |

| Payment term | T/T, L/C |