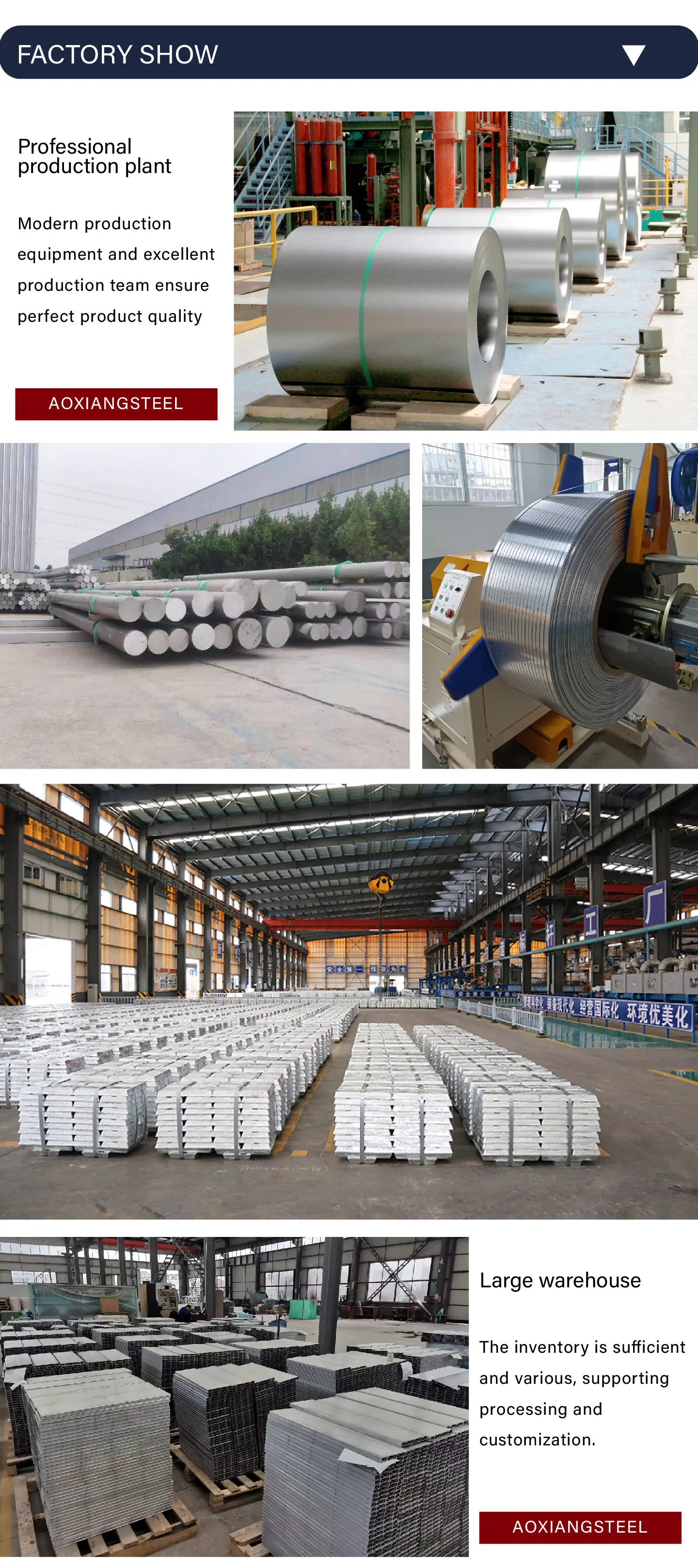

Aluminium Coil for Marine

Aluminum coils for marine applications are commonly used for manufacturing boat hulls, decks, and other structural components.

Request A Quote?

Product Details

Aluminum coils for marine applications are commonly used for manufacturing boat hulls, decks, and other structural components.

Marine-grade aluminum alloys are preferred due to their excellent corrosion resistance, lightweight nature, and high strength-to-weight ratio.

When selecting an aluminum coil for marine purposes, it is important to consider the following factors:

1. Alloy: Opt for marine-grade alloys, such as 5052 or 5083. which are specifically designed to withstand saltwater exposure and marine environments.

2. Corrosion Resistance: Look for aluminum coils with enhanced corrosion resistance properties, as they will be exposed to saltwater, seawater, and other corrosive elements.

3. Strength: The coil should possess sufficient strength to provide structural integrity to the marine vessel. Marine-grade aluminum alloys typically have higher tensile strength compared to standard aluminum alloys.

4. Formability: Consider the coil’s formability and ease of fabrication, as it will be shaped and formed into various parts during the boat-building process.

5. Surface Finish: The quality of the surface finish is important for both aesthetics and durability. A smooth and well-treated surface will resist corrosion and enhance the overall appearance of the vessel.

It is recommended to consult with aluminum suppliers or manufacturers specializing in marine-grade aluminum to ensure you obtain the most suitable aluminum coil for your specific marine application.